|

This isn't a knock on the Icom 7300 by any means - it is a pretty slick little radio, and it's really cool to see the newer SDR technology available from a major player, at a price-point that can't be beat. It just isn't what I decided to get :-) As I've been building out my new shack, I spent a good amount of time saving my pennies and debating what rig would become the "main" box for the shack. With contributions towards savings, retirement, private school tuition and future college for 3 kids, etc. I had to be wise with my money, so even though it was tempting to take my annual bonus and run off and grab an Icom 7610, or a Flex 6400M, my YL gently reminded me that we had other priorities, so I ended up looking in the $1,000 - $1,500 dollar range for my new rig. With all the talk about the 7300, Icom's rig did seem like a no-brainer. I had to remember however, that for me a large part of ham radio is just the fun of it, and I wanted the radio in my shack to be fun for me. For me that means big, buttons, and lots of ways to interconnect with other equipment. Even though the receive performance of the 7300 is awesome, it's wiz-bang touch screen stuff fell just a bit short on the fun-meter for me. After hanging out and playing for a while at the "local" HRO in Wilmington Delaware, what pegged the fun meter for me was the Yeasu FTDX3000, which at nearly $600 off normal retail during Hamvention week, brought this radio down into my price-range. With my new rig in hand, you can also finally see my vision of the "through the wall" equipment starting to come together. With a combination of MDF, my table saw, my oscillating tool, a drill, and some brackets, I now have the radio mounted in it's home. The next step is making the face frame to go around the rig to make it pretty, but you get the idea...

4 Comments

Post contains affiliate links

Over the last couple months I've shared some nuggets of information here, on Twitter, and on Instagram, about my dc power distribution for my on-going shack build. I promised some more details, so here they come!

Pretty early on in the design of my shack, I knew I wanted to have a 12v power distribution arrangement of some type. The most obvious reason was because that's what most of our gear runs on, but secondarily, I wanted to make sure that some of my task lighting and other shack "appliances" are also 12v, so that I would have the option of some solar, battery-back up, etc. in the future. This dictated my basic requirements for dc distribution - a hefty power supply and/or batter charger, fuses or breakers for the different 12v circuits, and some basic control options (relays or switches) to turn stuff on and off.

Step 1 in this process - figure out what to mount all the stuff in! I personally like the look and workmanship of a proper cabinet and din rail. What I ended up using for the box was something re-purposed. I used to lug around some work equipment for training purposes, but with changes in products, and some abuse from being on so many planes, some of the equipment needed to be scrapped, so after gutting, I kept one of the back-boxes. To meet my power / future battery charging needs, I ordered a 75amp power supply/charger, and started with that:

While I can't help you out with sourcing a back-box exactly like this, I can share a link for the power supply. I chose the IOTA DLS-75 because they can be had relatively inexpensively, and for a large switcher, they seem to get pretty decent reviews from other hams in regards to being RF quiet etc. The model I got is a combined power supply / batter charger, so it will also cover me for future battery-backup when I'm ready to add it.

Next in line (because I like the tidiness that can be created using din-rail stuff) I ordered up some din rail and some DC breakers. To start, I grabbed a 63 amp breaker for the "main" a 25 amp breaker to power the main rig, and a 20 amp breaker to wire up misc. 12 v lighting etc. I also grabbed some bus-bar, and these nifty little din-rail mount plates to hold a raspberry pi and a couple arduino uno cards. The plan for these was to build in some power monitoring and logging. I also picked up a little arduino hat that breaks out screw terminals for the input and output pins, to make it easier to wire up sensors. It also gives a small prototyping area in the center, which may or may not be useful :-)

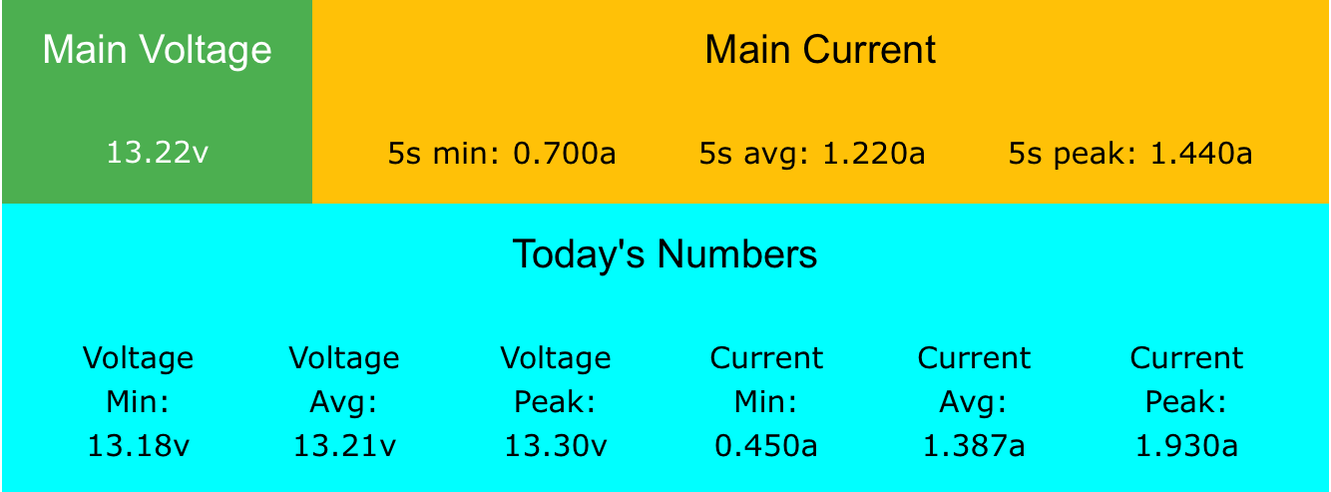

Once I had this stuff and started wiring things up, I realized pretty quickly that I had a noisy fan in the power supply I got, so I ordered a replacement fan. At the same time, I ordered a couple other tidbits: The little green thing on the right is a din-rail mount dc current sensor, good for up to 100 amps! There's still a lot of bits I need to add, and wiring to tidy up as I do it, but as I started piecing things together, this is what it started to look like: Wiring up the DC current sensor was pretty easy - feed it power with anything from 8 - 35 volts, and then read the voltage output from the sensor connection terminals. 2.5 volts is 0 amps, and up or down from there gives your your current in either direction (after throwing it into a quick formula to convert the voltage to current). Since this measures current in both directions, you could easily use this to monitory battery charging/discharging as well! To monitor the main voltage, I just whipped up a little voltage divider to feed the arduino. Rather than use something specified somewhere, I just sat down with this calculator, and the pile of resistors in my junk-box until I found a combo I had that worked well. I then wired up the resistors into a harness, so the voltage divider is now in-line in the wiring between the the arduino and the bus bars where I connected to sample the voltage. With basic power and sensors wired up, I mounted up the front panel of the box, which has the display for the Raspberry Pi mounted to it. (If you missed it, I shared some info when I did that several weeks ago - you can check out the details here.) Next, I whipped up some code! To save time for those who may feel this post is already getting a little long, I'll share the details on that code another time, but if you're super interested, drop me a note and I will send you copies to do with as you please. The quick summary is that I have the Ardunio reading the voltage and current sensors, and it dumps that data out of it's serial port. I then have the raspberry Pi running a LAMP stack. A Python script running on the Pi reads the serial data and stores it in a mySQL database so I can explore and manipulate the data it captures using all the mySQL stuff I'm accustomed to. I also whipped up a little PHP web site (only accessible on my local network at the moment) that displays the data. I have the display on the front of the power box showing the page in full-screen mode all the time, and I can also pull it up on my browser any time I want as well - it's fun to pull it up and make contacts while watching the numbers change :-) So there you have it - the shack power distribution update! There's still a lot of work to do on this, but at the moment I have functioning power for the rig and some task lights, and I'm recording data about my power usage. This means that when I get ready to drop some big back-up batteries on this situation, I'll have a good idea of what size of batteries to shoot for. 73 for now! |

Categories

All

- N3VEM - Welcome to my Ham Radio Blog! This blog was started primarily to share my two concurrent shack builds - my mobile station and my home station. Over time, this has grown to include sharing about my operations, and general radio-related thoughts that I have as a newer operator. Proving that hams do indeed still build stuff!

100 Watts and Wire is an awesome community, based around an excellent podcast.

Archives

September 2020

|

RSS Feed

RSS Feed