The EPA recommends radon remediation if levels are at or above 4 pCi/L. Before starting my work, our radon tested at just over 17 pCi/L (WOW!) After my work installing the radon piping and fan and sealing up all the cracks and such in the concrete slab, our new test averaged at 1 pCi/L. (The test is done with two samples - one sample was 0.6, the other 1.4) Awesome!

|

Pretend you're standing next to me in my future ham shack (I started working on it waaayyy back here.) Now, take a deep breath. What's that filling your lungs? Fresh, radon-free (nearly) air! Several of my recent posts told the saga of my DIY installation of a radon remediation system (Health and Welfare, Blowin' in the Wind) and now the results are in! The EPA recommends radon remediation if levels are at or above 4 pCi/L. Before starting my work, our radon tested at just over 17 pCi/L (WOW!) After my work installing the radon piping and fan and sealing up all the cracks and such in the concrete slab, our new test averaged at 1 pCi/L. (The test is done with two samples - one sample was 0.6, the other 1.4) Awesome! In other news, I also did some thumping around in my attic recently. Eventually I will have some roof-mounted antenna's - mostly my VHF/UHF stuff. During our addition project I ran empty conduit up through the walls, but actually getting to the top of the conduit wasn't easy. To make access to this spot a little easier, I spent an evening this week carrying ripped-down pieces of plywood up into my attic, to make a walkway across the joists from the access hatch, to the far end of the house. This will make it easier to get to the point where the coax goes from outside to inside, and will also make it easier for me to finally get that fan dipole installed in the attic that I wanted to stick up there, just to play around with. Now I just need to add lights (luckily I have an AC circuit pulled for this - I just haven't connected it yet...) Bye for now!

0 Comments

Post Contains Affiliate Links I have another shack update to share! With the utility room finished up (I just wrote about that recently), the cat boxes are moved, and I was able to do my final prep before I start to hang drywall in the shack and rec room. For me, there were 2 things left that I wanted to do before hanging the drywall. The first was to add insulation to the stud bays. In the process of doing that I also boxed out the location where I will be attaching a metal panel that will serve 2 purposes:

The second thing on my list was to get the main power feed sheathed in conduit where it would be exposed, and connected to the new sub-panel in the shack. With that done, I was able to connect a temporary circuit to have a couple lights and a receptacle. Now I can see while I work, without needing to drag extension cords across the other parts of the basement! Why the insulation you ask? It's actually a pretty basic answer - sound dampening. Now, there is a difference between sound-proofing, and sound dampening, and I think sometimes people get confused about what types of products do what function. Any porous material, like insulation, or those foam egg crate panels you can hang on walls (which I plan on doing in some areas!), the corner bass traps that you can find online, will do a fine job of sound dampening. That basically means they can help improve the acoustics of a room by helping to prevent reflections, echos, etc. They WONT sound-proof your room. Outright sound-proofing is a different beast, that as hams, we probably don't need to worry about. The best way to really get sound-proofing is mass - i.e. thick concrete walls. For me, sound-proofing is already about as good as I can expect it because my room happens to be a concrete cube- I just wanted to fill the hollow, framed, walls with something so that my small room doesn't have weird echos as I talk on the radio, and do my conference and video calls for work! What do you think?

More progress on the home shack! Well, kind of...first, let me tell you what I was working on, and then I'll roll into the ham radio / shack progress connection. We currently share our home with 3 furry friends (or maybe, they share their home with us?) Anyway, their litter boxes have been residing in the end of the unfinished part of the basement that will eventually be the rec room. (If you'll recall, from all the way back here, the room that's becoming my shack used to be the "cat room.") We wanted to transition their box area to the back of the new utility space, but a couple of them are older cats, which means they sometimes have questionable aim... Anybody who has ever tried to get the smell of cat pee out of anything knows what a chore that can turn into. Rather than have our utility room end up smelling like (well, you know....) we decided to make it a very easily cleanable space. With that goal in mind, I hung plywood on the walls and painted it, to seal it up. There was still that floor to deal with though... So, after some scrubbing, some etching, and some more scrubbing, I epoxy coated the floor to accomplish 2 things - to keep any "accidents" from soaking in and become a permanent part of the milieu, and to make any needed cleanups simple... With the floor sealed, and easily wipe-able, It was time to finish up the other things. I added some trim (PVC trim, for obvious reasons), some silicone to seal around the trim, and some of those beautiful truck-stop-bathroom wall panels. The final effect makes for a tidy utility room, but also a place to put the cat boxes that will be easy to clean. So what is the ham radio and shack progress connection? There's really 2 parts to that:

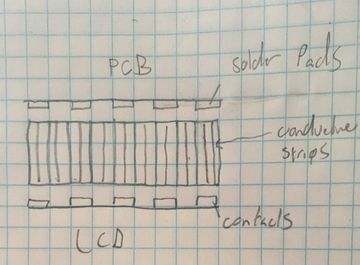

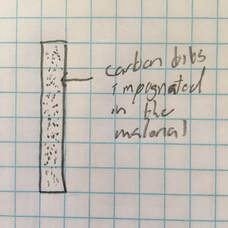

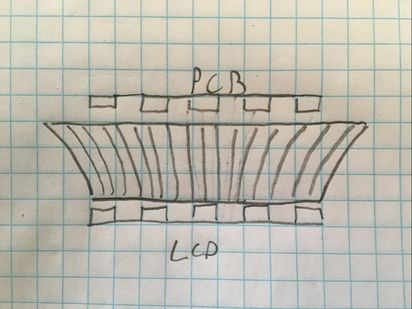

Remember when I put the radon fan in? The thing I didn't explain at that time was the big gray box with the ground rod right next to it....that's where the conduit in the utility room goes. When we finish grading for the flower garden on this side of the house, the ground level will come up to just below the top of this box. I'm excited to have another thing done (even if it is just the fancy restroom for the cats), especially when its one that moves me closer to having my ham shack done! Say what?!  No, I haven't completely lost my mind and started genetic experiments to try and create stretchy wildlife that will transfer an image from one sheet of paper to another (remember carbon paper?) These are all words that apply to a type of connector that I didn't have much familiarity with until a couple weeks ago, which also happen to be present in a lot of electronic devices - including our ham radios! To some folks this might be old hat, but for me it was another learning experience that I'd like to share, because I'm sure there are other people out there like me, always learning new things. With that little tidbit, here's my story - enjoy! One of the local club members had a radio that didn't seem to be making proper contact for the mic, because it wasn't always keying up, or would key up, but no audio would be transmitted, etc. In the process of plugging the mic in and out to try to figure out the problem, the little retention clip on the RJ45 plug broke off, so he needed to put a new plug on his mic cord. I helped him put the new plug on, but the mic jack was still being finicky. I decided to take the radio apart to see if the mic jack was one that could be easily removed from the board and replaced. After doing that, taking pictures to see about ordering a new jack, and reassembling the radio, the LCD display had missing segments. Uh Oh. I ended up taking the radio home to spend some time doing battle with it, to get it working again. Inside the radio there was a lot of oily residue, which I suppose was contact cleaner. Now, many contact cleaners and oils that are used to coat and clean electronics are non-conductive, but I have learned from something we found at work, that non-conductive liquids can cause problems, because sometimes in the process of them doing their thing, they just move dirt around, and if the dirt gets in the wrong place (like between relay contacts or into pizeo buzzers), it can do strange things. File away that note, it will come back shortly.  An elastomeric connector - similar to the one in the radio I was working on. An elastomeric connector - similar to the one in the radio I was working on. In the process of taking the radio apart, I also came across the funny rubber strip (elastomeric connector), often called a Zebra (brand name) connector, that makes the contact between the circuit board and the LCD display. I've seen these before, but never really messed with one - all I knew was that through some unknown magic it conducted electricity between these two parts. My gut told me that this magic wasn't happening, so I did a little Googling, and determined that I might just have some dirt or oil (remember that thing I mentioned in the last paragraph...) that was keeping this little connector from working, and that cleaning with alcohol was the ticket. With that bit of information, out came the rubber gloves, q-tips, and alcohol (isopropyl, not Jameson). I spent a good bit of time cleaning all the old residue out of the radio. After all the detailed cleaning work the result was.......nada. Still the same problem. I figured that maybe the easiest thing to do was to just get a new Zebra connector. The Icom service manual for the 2100H had them listed with a part number, so I called Icom. It turns out they don't have parts available for this radio any longer. My next stop was to see what I could find via the electronic suppliers, but I came up short. I did happen to stumble on the website of a company that manufactures these things, and does prototyping service, however. I called them in the off-chance that maybe they do some retail sales. That's where my luck changed - the guy that answered the phone just happened to be another ham, named Don - what are the odds?! Anyway, because of the ham-brotherhood he spent some time talking with me about these connectors (the company he works for only does manufacturing for wholesale, or larger orders than I would have been making.) Basically, the way these connectors are made, is in super-thin layers. The first layer is basically just a rubber-like material, the next layer is the same stuff, impregnated with carbon, the next layer is just the rubber-like material, etc. This means that every other layer is conductive, so you end up with a strip that is something like this: The thing that I found most interesting, that Don explained to me, is that these strips aren't actually completely conductive - if we zoom in on a single strip, at the microscopic level, what we have is something like this: Basically, the little bits of Carbon have to touch each other to conduct electricity, so these connectors have to be under enough pressure to squeeze them all together, but not so much pressure that it deforms the strip and causes things to make / not make contact where they are / are not supposed to. Don also explained to me, that these strips can unfortunately have a "memory" so sometimes after being in use for a while, they don't really go back together like we'd expect. Also, because of the nature of how these strips work, they need to be supported as you put things together, so that they line up properly. In the case of the Icom rig, there are plastic pieces that go in place around this strip to hold it, but from this conversation, I realized what my problem was. Whether it was from manufacturing, or from "memory" over time, the strip in this rig was actually too long, from side to side. If it was this way from the start, the machines that assemble the radio probably do all the hard work, and kind of "force" the rubber down to the size needed as it is assembled. Regardless of how it happened, I could tell by looking at the strip (and measuring it) that it was several mm too long. When I put it down into it's slot, I had to force the bottom, which made the sides flare out, giving me something like this: Pretty obvious now what was going on, isn't it? With that bit of knowledge, I trimmed the strip down to it's proper length, put everything together, and presto: As a side benefit, I think some of the oil and dust mixture may have been the root cause of the mic connection issue as well, because after finally getting everything clean, and back together, the radio is working like new. In the true ham-spirit, the whole repair didn't cost anything other than my time, so everyone's wallets are happy as well! P.S. As a side note - I wouldn't recommend randomly cutting connectors down if you have the same problem - I have to assume that most radios come from the factory with everything cut to the proper size - this was probably just a fluke. If you have similar issues though, you can try cleaning the ends of the connector with alcohol, using small strips of tape to "shim" around the connector (another tip from Don!) to help it stay in the right place, use tape or washer shims under/over the boards or to help the board put additional compression on the connector, etc. You get the idea - whatever it takes to hold the thing in place, and make sure there is enough "squeeze" to make the little carbon atoms touch each other!

Well.....hello there. Welcome to 2018! Now that the holidays are in the bag, it's time to start running full steam ahead with a new year of work, projects, school, volunteerism or whatever else takes up your time (or if you're like me, a little of all the above!) Rather than write resolutions this year, I decided to point out the fact that, just like a large portion of hams, at any given time I have several unfinished projects. There was a time when this would make me completely bonkers, but I've really come to terms with it, and now view it as having many opportunities to work on things when I have some free time. With that thought in mind, here are my "opportunities" that I'm starting 2018 with, that all of you will get to follow along with as time marches on throughout this next year - enjoy! Home Shack Build

Current status: dry-walling started project: way back here Mobile Shack Current status: in-use, but always in progress started project: also, way back here Crowd Sourced Project Current status: ready to start mounting hardware started project: a few months ago Learning CW Current status: 5wpm. Haven't made a CW contact for a couple months. Started project: when I started activating parks, post NPOTA Little Helper's Analyzer Current Status: not done. My little helper and I are working on building the HR360 AA project when we get time, and when her little brother isn't around to try and steal the parts. Started Project: I'd have to check my Digi-key receipt..... The semi-secret, somewhat radio related project Current status: In the garage. I gave sneak peeks on Instagram a while back, but still need to put on the finishing touches, and then explain what it is and how it's radio-related. Started project: Sometime around my YL's last birthday. The Secret Project Current Status: Yes, it's still going on - but this one I insist on finishing before I share. It will (someday) be a series of posts, back-to-back Started project: Scared to admit how long ago at this point.... Those things alone are enough to keep me busy for the next 12 months, but I'll invariably end up picking up another project or two along the way, so I hope you'll check back often to see what I'm up to (and maybe even give your input and advice!) So for now, I'm out - catch you later! |

Categories

All

- N3VEM - Welcome to my Ham Radio Blog! This blog was started primarily to share my two concurrent shack builds - my mobile station and my home station. Over time, this has grown to include sharing about my operations, and general radio-related thoughts that I have as a newer operator. Proving that hams do indeed still build stuff!

100 Watts and Wire is an awesome community, based around an excellent podcast.

Archives

September 2020

|

RSS Feed

RSS Feed