- I fastened the part in place with silicone adhesive. I thought that between the tight friction fit and this adhesive the part would be fairly permanent, but alas, the glue started coming loose, and I noticed some wiggling when I manipulated the radio controls.

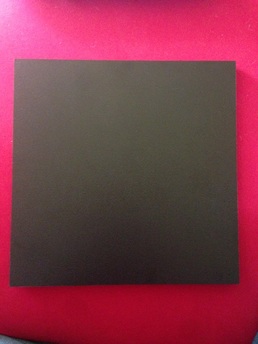

- The plastic I used to make the part was a cheap cutting board - the material was great, but apparently it doesn't hold paint well, and the paint started to flake off.

Panel 2.0

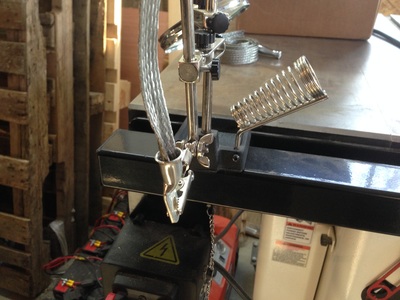

| Once I had this done and screwed in place, I traced the outline of the old panel onto this new piece of plastic, ordered from Tap Plastics. For the material and size this place was the best price I found in my short search. It's the same type of material as cutting boards (HDPE) and is marketed for use in marine applications. I liked it because I knew the material was the type I wanted, and I could order it in black, so I wouldn't have to worry about paint chipping. As a bonus, I like the texture on this better than the texture on the cutting board that I had used previously. |

| I guess it doesn't look much different than it did in the original pictures, but it looks better than it did yesterday, with the paint flaking off the first part I made. It also feels a lot more solid - everything is screwed fast, and staying put. P.S. I also drilled another hole and put in another NMO mount recently - I'll fill you in on that part of the project as soon as get to finish it.... di-di-di dah-di-dah |

RSS Feed

RSS Feed