With that being said, if you want to read about how my junk-mast project got started, check out Part 1 of the story before continuing on here. If you already read Part 1, or if you just like to shoot from the hip and decided you'll figure it out as you go - read on!

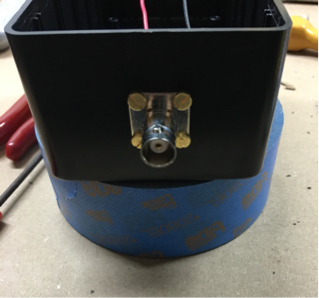

At the point I left off, I had the mast, and I had inserted a piece of broom handle that had painter's pole thread on the end, and I had started fixing that all together. Sometime shortly after that post I also stumbled onto a short section of scrap PVC that I needed to make a "splint" over a hole that had been drilled in the bottom section of the pole. Now that you're caught up, here we go!

|

With the top of the mast done, I wanted to add guy rings, so that I could attach ropes etc. to keep things tall and straight. Thankfully, I managed to dig up some scrap pieces of HDPE plastic that I had left over from the mounting panel that I made for the control head of the radio in my car (you can read about that project in my post called New and Improved.) If you don't happen to have this stuff lying around, I'd recommend grabbing some, as it comes in handy for all kinds of radio-related projects where you need to make mounting panels, brackets, etc. and you need something that looks nice, and isn't metal.

|

|

RSS Feed

RSS Feed