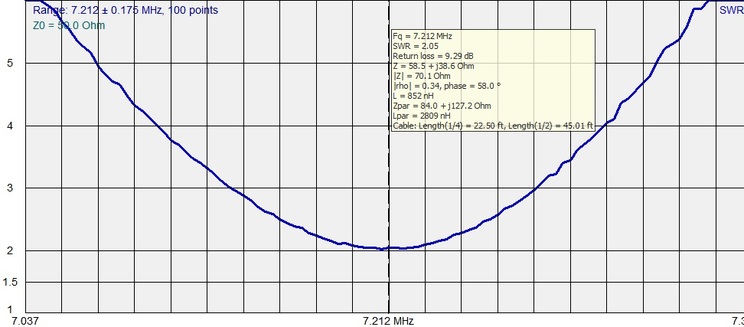

Like many things, there is a lot of back forth when questions like these come up. There are things like questions about how much it really matters when you consider how compromised a mobile antenna is, where is the matching device located, how long is the coax, etc. With that in mind, I'm considering a small experiment:

- Put in the whip matched from resonance, and set the MFJ matching unit to the appropriate setting.

- Put the field strength meter some set distance from the antenna (15 feet?)

- Transmit a carrier on low power - maybe 5 or 10 watts

- Calibrate the field strength meter to mid-scale

- Switch to the second whip, matched from low SWR, and set the MFJ matching unit to the appropriate setting.

- Transmit a carrier on the same low power setting as step 3

- Compare the reading on the field strength meter

RSS Feed

RSS Feed